What to consider when ordering a letter box

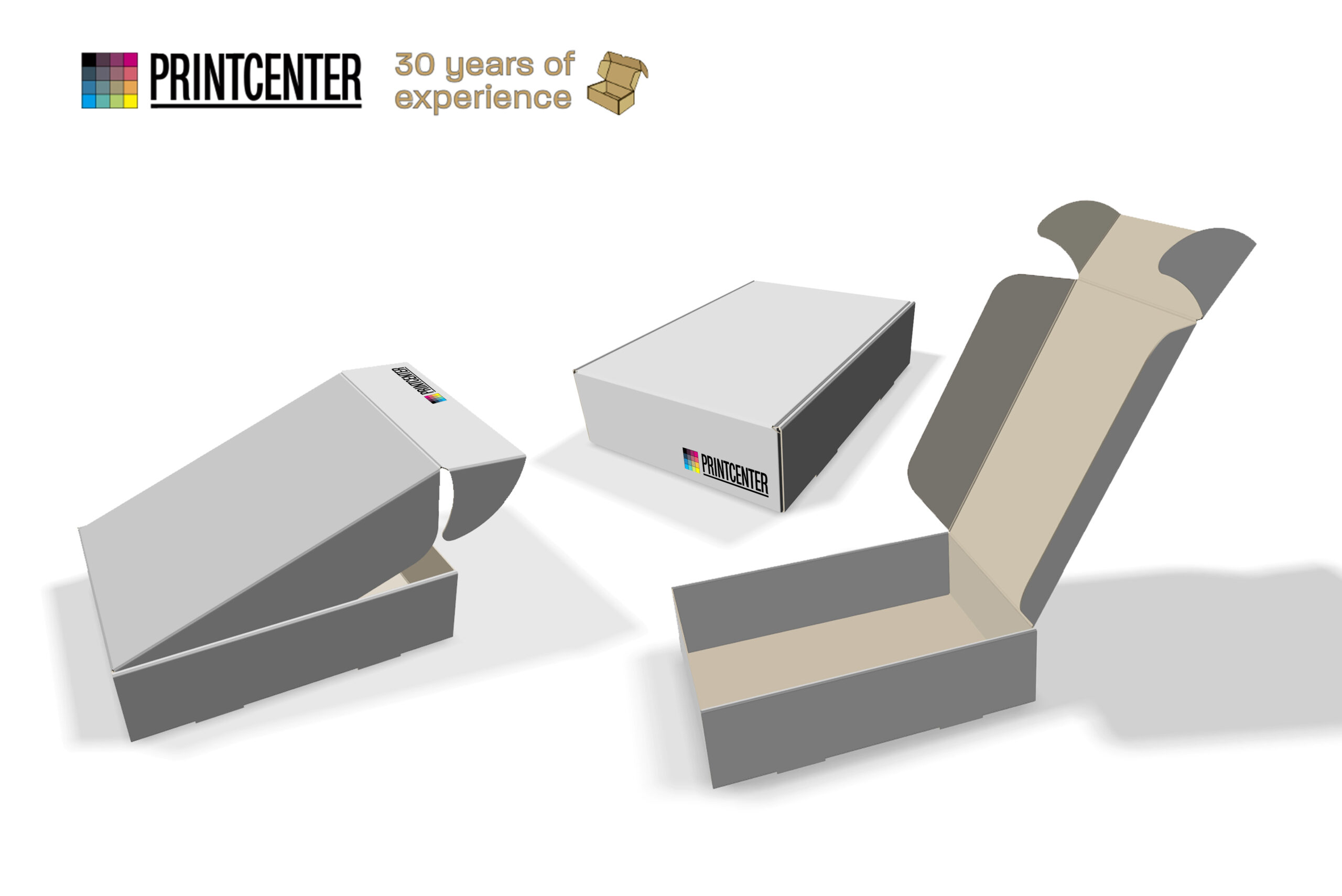

The most popular mailbox used is fefco 0427

Advantages of the box are its easy assembly, self-locking solution and the small storage space it takes up. The double sides add strength to the packaging.

What to consider when ordering such a box?

First of all, you should determine the product dimensions that need to go into the box. The weight that the box has to carry should not be overlooked. The dimensions and the weight determine the material from which the box is made. Thanks to a simple solution, the box can be made from a variety of corrugated cardboard. Mini corrugated cardboard, 3mm corrugated cardboard, brown corrugated cardboard, white corrugated cardboard, etc. In addition, a smaller box can also be made from cardboard.

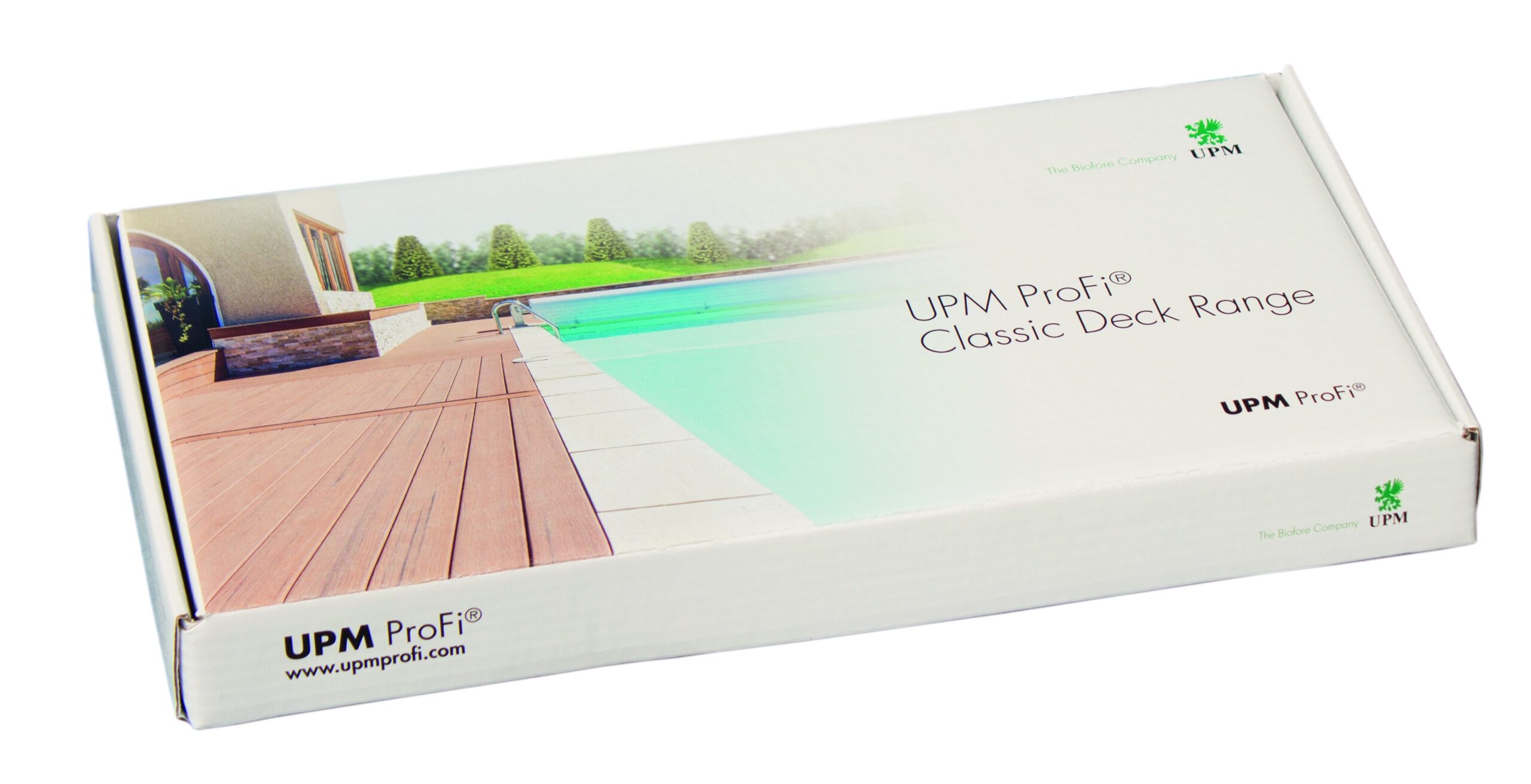

There are a lot of options for this box, both in terms of materials and printing solutions. The best-selling box is made of white mini fabric with 4/0 printing.

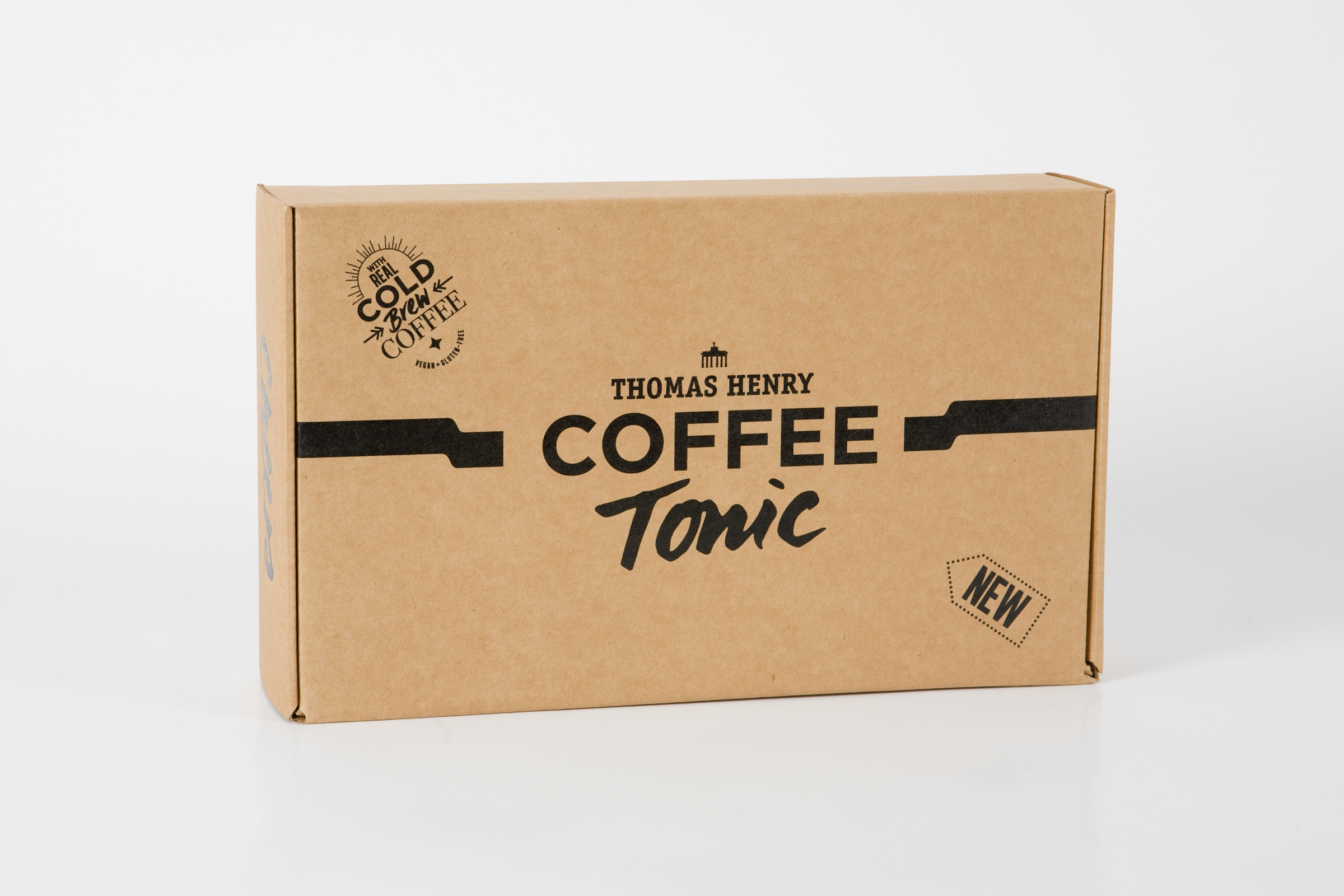

Different printing solutions are possible: 1/0 – one colour print on the outside of the box. Most commonly used on plain brown boxes.

2/0 – two-colour print on the outside of the box. If it is necessary to emphasize a logo or some other message on the box.

4/0 – through 4 colour printing on the outside of the box. Used on the outside of a white box.

In addition to printing on the outside, it is also possible to print on the inside of the box.

E.g. 4/1 – four-colour piece on the outside and one-colour print on the inside. or 4/4 – both inside and outside print through four colours.

This gives the opportunity to surprise the customer with a special message when opening the box.

The top surface of the box can be covered with different laminates:

Matt laminate – adds strength and durability by making the surface of the box matte.

Gloss laminate – adds the same properties as matt laminate but the surface of the box remains glossy.

Matt and gloss laminates also have food contact certification.

Soft touch laminate – is one of the most eccentric finishes. In addition to protecting the surface, it adds a very attractive velvety feel to the touch.

In addition, UV varnish can be applied to the box:

It’s the easiest way to add sparkle to your packaging. Use the varnish to highlight details or elements and create contrast between surfaces. Today’s UV varnishes are environmentally friendly as they dry quickly and do not contain volatile organic compounds that are harmful to the environment.

The eye-catching design is provided by the foil print:

The foil is applied to the surface of the box using heat and pressure. The main property of foil is to give the product a metallic glossy finish.

Gold and silver are commonly used but foil is also available in other colours. Hologram foil makes the most special impression.

If you’re going to make a box as eye-catching as possible, then you can’t miss out on a die-cut and blind print:

Embossing allows the logo to be pressed into the box. Die-cutting allows the logo to be brought out of the box. (Both technologies leave the logo mirrored on the other side.)

In addition to the different printing solutions, it is possible to add a window to the box, either open or covered with transparent plastic. If this kind of packaging appeals to you but your products need extra protection, you can always add an extra insert inside the box to keep your smaller products neatly in place and give extra protection to delicate products.

Simple packaging, endless possibilities.